Your vehicle is only as good as its weakest link, and for Clinical Racing‘s Class 2000 truck, that was their transmission. The team turned to TCI Automotive to help solve a part of their drivetrain wreaking havoc during the first half of their season.

Desert racing and off-roading, in general, place every component of the vehicle under extreme pressure and loads. The more the car gets pushed, the more the parts are pushed, and the faster the weak link gets discovered.

BEHIND THE GEARS

Clinical Racing’s truck is powered by a Gen V LT1 engine with around 550 horsepower and 450 lb-ft of torque. Getting the power from the engine to the wheels and not having any issues in between is where the team was running into problems.

The team began with a 4L60e but soon came to find out it couldn’t keep up with the abuse it was seeing. The overdrive and computer-controlled shifting made staying in the right gear in specific terrain among a few issues the team would see competing in the Southern California desert.

Given all the details and specs on the build, the proper transmission and torque converter were selected with the help of TCI Automotive. TCI has been an industry leader in the performance transmission market for over 50 years.

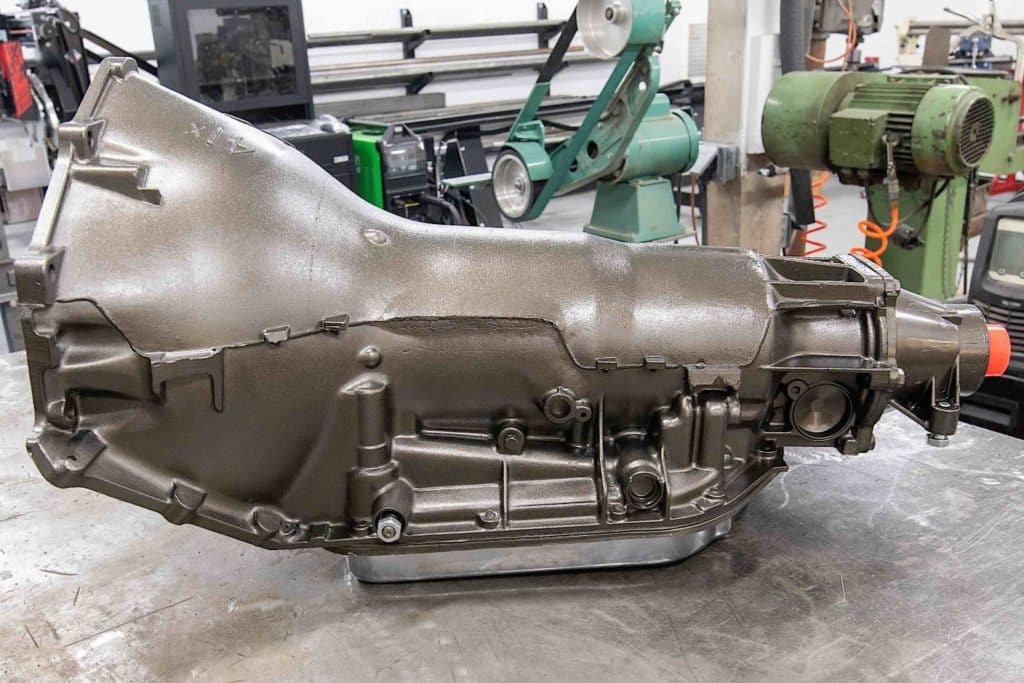

The final choice was their full manual, four-inch tail shaft, reverse shift pattern, non-lock-up with high-performance clutches TH400 (PN 212015). TCI Automotive also recommended the StreetFighter Torque Converter with a 3,000-3,400 RPM stall (PN 241001) and SFI-rated GM LT1 flexplate (PN 399860).

“TCI transmissions are remanufactured, not just rebuilt,” Rusty Sampsel of TCI explained. “Critical components are either replaced or machined to meet our specifications which include high-quality clutches, bands, races, bushings, bearings, and sprags are used in every unit we build.”

“We are always working to find improvements and refine our products,” Sampsel continued. “We are committed to keeping a pulse on the industry so we can offer products with the most value to our customers.”

Designed for high-RPM GM LT1/LT4 engines, the SFI 29.2 certified 1-piece flexplate we went with is made from 4140 forged steel and features a hobbed-on ring gear and robotic tig-welded converter spacers. Gas nitriding provides extra surface hardness and strength, while E-coating offers corrosion protection.

“The TCI flexplate features CNC-milled pockets, and lightening holes reduce the flexplate’s rotating mass and overall weight,” Sampsel said. “Weighing only 7.6 pounds, it is built to withstand over 12,000 RPM. Weighing significantly less than a factory unit this flexplate delivers more power to the rear wheels by reducing rotating mass.”

“Designed with the more radical builds in mind, the Street Fighter torque converter benefits machines with performance cams, aftermarket carbs, and higher compression ratios to bring the launch RPM in line with the performance enhancements,” Sampsel continued. “The Street Fighter torque converter takes advantage of horsepower gains found in higher RPM ranges.”

Having the right parts for the specific application is essential and will increase the overall performance and increase the durability of the vehicle. The wrong parts installed in the incorrect application means time stuck on the side of the road or the trail.

NO STRINGS ATTACHED

Less is more. Having less to worry about in an off-road vehicle is essential and can make time in the dirt less stressful. More bells and whistles aren’t always a good thing with the ability to have more things go wrong.

Running several redundant systems like two fuel pumps, two batteries, and manual overrides on everything possible is important in a serious off-road build and can prevent being stranded. Clinical Racing would have less things to worry about installing the TCI Automotive TH400.

The TH400 would be the upgrade needed and one less electronic component to worry about race day. Electronics weren’t the main reason for the upgrade. The overall strength of the TH400 was a key factor.

Featuring a beefier shaft, gears, simple design, less to go wrong were all considered when switching from the 4L60e. But when it comes down to it, a TH400 is genuinely a truck transmission.

Thankfully with the truck being a race truck, it made the install relatively easy. Many of the factory parts that would be in the way or tight areas were gone, and the transmission tunnel was easy to access.

The team was no stranger to removing the 4L60e in the truck, as this final time was the fifth time the transmission had been out of the truck. The team had added to make pulling the transmission easier by adding a patch panel inside the truck that gave them easy access to the transmission fittings on the case.

Installing the flexplate was straightforward and simply removed the one currently being used for the TCI Automotive flexplate. Before the TH400 was lifted to be matted with the LT376/535, the torque converter was filled with transmission fluid and properly seated on the transmission.

Having a different transmission mount, the team did have to modify the existing transmission crossmember to support the TH400. A couple of new plates welded to the current crossmember gave Clinical Racing a new place to mount the transmission.

One visible difference between a 4L60e and the TH400 is that the bell housing is molded into the TH400 casting compared to the 4L60e. While there are different TH400 case options, the molded TH400 case is still very similar in size to the 4L60e.

With everything bolted up, fluids topped off; it was time to take the truck out for a drive to see and feel the improvements of the upgrade.

IN THE DIRT

Some modifications and additions take time to see or feel the difference, but for this upgrade, Clinical Racing felt the improvement on the first drive. Pulling the truck out of the shop the first time, the difference was apparent.

Besides the fact that shifting was done manually now, the truck drove and felt better in each gear made it a night and day difference over the 4L60e. The truck felt more responsive and prepared for the abuse that it would be seeing in the desert.

The team went through three transmissions in the first three races. Since the TH400 was installed, the team did three more races and over 400 miles, all with no issues.

For more information on TCI Automotive and to find the right product for your ride, be sure to visit their website.